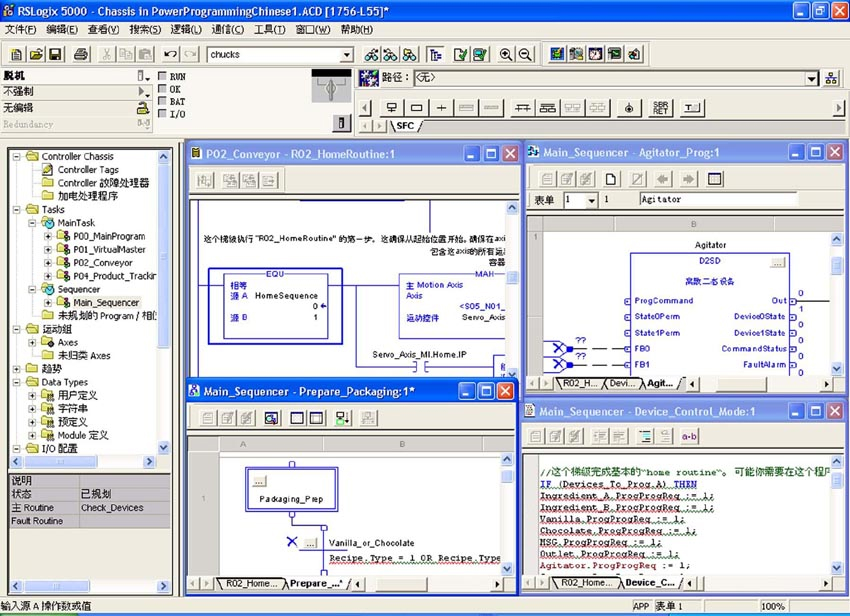

Note that the procedure is similar for other models of PLC, but the cards will be slightly different. These modules may be added into the RSLogix or Studio 5000 Environment under the Expansion I/O menu. The CompactLogix PLC used in this tutorial is equipped with a backplane which allows it to communicate to the cards attached to the right of the processor. RSLogix Studio 5000 Adding an Analog Input card 1769-IF8 into the Projectīefore we can configure the input card, we need to add it into our project. Additionally, we will be programming a simple routine which is used as a way to scale the input just as it would be in a real control system.

We will be utilizing an external signal from an Automation Direct CLICK PLC in order to simulate a specific signal. In this article, we will be exploring & going over the steps required in order to configure and receive inputs on this module. It’s an easy to program module in RSLogix & Studio 5000 & it provides an excellent means of receiving analog sensor data. It provides 8 channels which may be configured for voltage or current signals. In the CompactLogix family of Programmable Logic Controllers, the most utilized analog input card is the 1769-IF8. At this point, the control system needs to provide an input capable of capturing this specific signal. These devices typically send a 4-20mA or a 0-10VDC signal back to the main panel. They are utilized for pressure sensors, temperature sensors, weight-scales, flow meters, level transmitters & other devices which report a range rather than a simple ON/OFF signal. It allows us to make changes before the circuit is implemented, reducing the risk of errors and accidents.Īnalog PLC Inputs are crucial for modern control systems. And seventh, it helps to identify potential risks and hazards associated with the circuit program. Thus, it provides greater flexibility in experimentation. Sixth, it allows for testing different scenarios without physical changes to the control circuit. Why? Because physical testing can be affected by external factors. Fifth, it provides a more accurate representation of the circuit's behavior than physical testing. Fourth, you gain an understanding of how the program works, how it interacts with various inputs, and how it produces outputs. Third, it allows for the testing of the circuit program without the need for actual hardware, which can save time and resources.

Second, you can identify design flaws and adjust parameters to improve the circuit's performance and safety. First, it allows for error detection in the control circuit program before it is implemented in real-life situations. Mastering the simulation process in Siemens Logo PLC can provide several benefits.

0 kommentar(er)

0 kommentar(er)